EU Standards and Considerations for Retaining Walls

Source: Internet

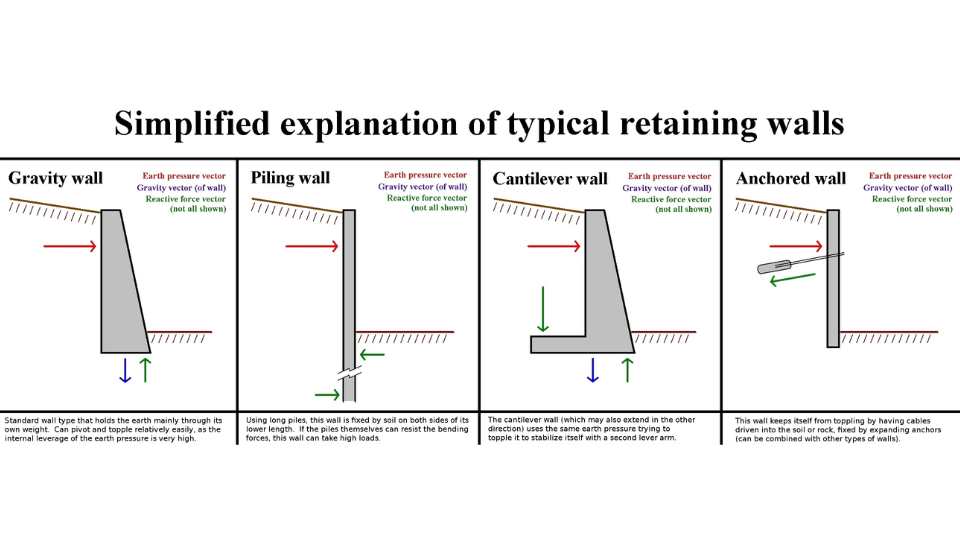

A retaining wall is a structure designed to hold back or retain soil, rock, or other materials behind it. It is commonly used to prevent the movement of earth and to create level surfaces in areas with slopes or elevation differences.

A retaining wall is a rigid or flexible structure that supports soil laterally so that it can be maintained at different levels on the two sides.

Types of Retaining Walls in EU Construction Projects

1. Berlin-Type Walls (Soldier Pile and Lagging Walls)

The Berlin-type retaining wall, also known as a soldier pile wall, is a flexible and economical earth retention system. It consists of vertical steel H-beams (soldier piles) installed at regular intervals, with horizontal lagging (typically timber, precast concrete, or steel panels) placed between them to retain soil.

Soldier Piles: Typically steel H-sections (e.g., HEA, HEB, HEM profiles). They carry the primary earth pressure and bending moments. Spacing depends on soil conditions, wall height, and lagging type, usually ranging from 1.5 m to 3.0 m.

Steel H-beams are driven or drilled into the ground at regular intervals along the planned wall alignment. The depth of embedment depends on the wall height and soil conditions.

Excavation and Lagging Installation: As excavation progresses in stages (typically 1 to 2 meters at a time), lagging is installed between the soldier piles to support the exposed soil face.

Support: The wall can be cantilevered for shallower excavations. For deeper excavations, it often requires additional support from ground anchors (tie-backs) or internal bracing (struts) to limit deflections and ensure stability.

Drainage: Berlin walls are inherently permeable due to gaps in lagging. Drainage behind the wall is crucial to prevent hydrostatic pressure buildup.

Watertightness: Generally not watertight unless special measures (e.g., geomembranes, grout between lagging) are taken, which increases cost and complexity.

Applications

• Temporary or permanent earth retention in urban excavations

• Sites with limited space and dry soil conditions

• Projects requiring minimal vibration during construction

• Temporary Works Design: Berlin walls are often temporary works. Design must comply with temporary works standards and safety regulations.

Advantages:

- Relatively fast and economical for temporary excavations.

- Flexible and adaptable to varying site conditions and wall geometries.

- H-beams can often be extracted and reused.

Disadvantages:

- Not inherently watertight.

- Can cause ground movements behind the wall, especially in soft soils.

- Limited in very soft or loose soils without extensive support.

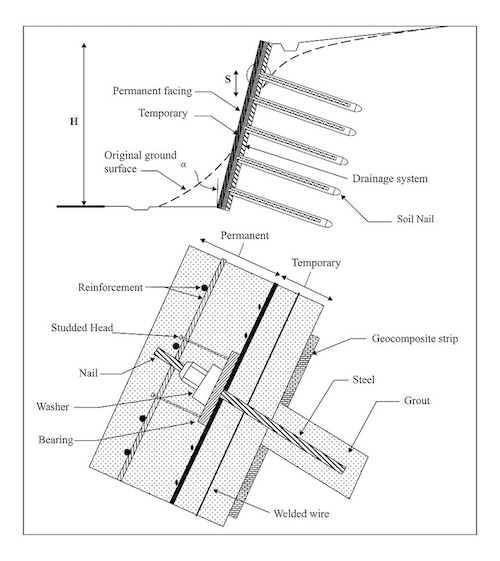

2. Soil Nailed Walls

Soil nailing is a technique used to reinforce and stabilize existing slopes or excavations. It involves inserting slender steel bars (nails) into the soil, which are then grouted in place. A facing, often shotcrete, is applied to the surface to provide additional stability.

Soil Nails: High-strength steel bars (solid or hollow, sometimes self-drilling) typically 15-40 mm in diameter, installed at a slight downward inclination (10-20 degrees from horizontal) and spaced 1-2 m horizontally and vertically. They are passive elements, mobilizing their tensile capacity as the soil deforms.

Grout: Cementitious grout (often neat cement slurry) is injected into the boreholes to bond the nail to the surrounding soil.

Applications

• Stabilization of steep slopes and retaining walls

• Excavations in urban areas with limited access

• Sites with cohesive soils above the groundwater table

Advantages:

- Cost-effective for stabilizing existing slopes or creating new retaining walls.

- Highly adaptable to complex geometries and irregular ground profiles.

- Minimal disturbance to adjacent structures due to sequential excavation.

- Generally vibration-free installation.

Disadvantages:

- Not suitable for very soft soils or significant groundwater without extensive measures.

- Requires skilled labor for shotcrete application and quality control.

- Can be affected by freeze-thaw cycles if not properly designed and drained.

3. Sheet Pile Retaining Walls

Sheet pile walls are constructed by driving prefabricated sections of steel, vinyl, or other materials into the ground to form a continuous barrier. They are commonly used for both temporary and permanent earth retention and are especially effective in waterfront structures.

Steel Sheet Piles: Most common. Available in various profiles (U-sections, Z-sections, straight web sections) that interlock to form a continuous barrier. High strength, durability, and can be reused.

Vinyl (PVC) Sheet Piles: Used for lighter loads, non-corrosive environments, and often for marine applications due to chemical resistance. Lower strength than steel.

Timber Sheet Piles: Less common for permanent structures, primarily for temporary works or non-critical applications.

Applications

• Waterfront structures like quay walls and cofferdams

• Deep excavations in urban environments

• Flood protection systems

Advantages:

- Fast installation (especially with vibratory hammers).

- Provides a relatively good groundwater cut-off.

- Suitable for a wide range of soil conditions.

- Can be used in limited access areas.

Disadvantages:

- High noise and vibration during installation (for driven piles).

- Potential for “kick-out” or leaning if not properly guided.

- Can be difficult to drive through obstructions (e.g., boulders, hard rock).

- Aesthetic limitations if exposed permanently without a facing.

4. Secant Pile Walls

Secant pile walls are formed by constructing interlocking reinforced concrete piles, alternating between primary (soft) and secondary (hard/reinforced) piles. This creates a nearly watertight and strong continuous wall.

Technical Details:

- Piles: Usually reinforced concrete bored piles. Diameter depends on wall height and soil conditions (e.g., 600 mm to 1500 mm).

- Overlap (Secant): The degree of overlap in secant piles is critical for watertightness, typically 75-150 mm.

- Reinforcement: Steel reinforcement cages are installed in the secondary (and sometimes primary) piles to provide structural strength.

- Support: Similar to other embedded walls, they can be cantilevered or supported by ground anchors or internal bracing.

Applications

- Deep basements

- Tunnels and shafts

- Water-retaining structures

- Excavations in urban or sensitive environments

Advantages:

- Minimal noise and vibration.

- Excellent groundwater cut-off (secant pile walls).

- High stiffness, resulting in small wall deflections.

- Can be constructed to significant depths.

Disadvantages:

- Higher cost than some other wall types.

- Longer construction time compared to driven piles.

- Requires specialized drilling equipment and skilled operators.

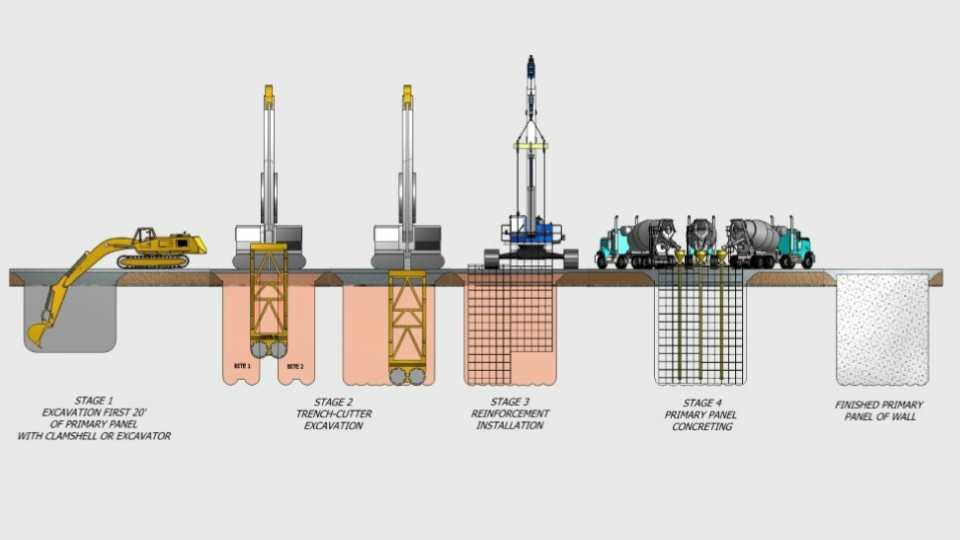

5. Diaphragm Walls (Slurry Walls)

Reinforced concrete walls constructed in the ground by excavating a narrow trench using a specialized grab or cutter, while simultaneously maintaining trench stability with a bentonite slurry. Reinforcement cages are then lowered into the slurry-filled trench, and concrete is tremied in, displacing the slurry.

Technical Details:

- Trench Excavation: Performed in panels using hydraulic grabs or hydrofraise (cutter-suction dredger) equipment.

- Bentonite Slurry: A thixotropic suspension of bentonite clay and water that forms a filter cake on the trench walls, providing hydrostatic pressure to prevent collapse.

- Reinforcement Cages: Large, fabricated steel reinforcement cages are lowered into the slurry-filled trench.

- Concreting: Concrete is placed from the bottom up using tremie pipes, displacing the bentonite slurry, which is collected and recycled.

- Panel Connections: Adjacent panels are constructed with special joints (e.g., stop-end tubes, pre-formed joints) to ensure continuity and watertightness.

Applications

- Metro stations

- Deep basement and underpass walls

- Cut-and-cover tunnels

- Water cutoff structures in high water tables

Advantages:

- Suitable for very deep excavations and complex geometries.

- Excellent groundwater cut-off.

- Minimal ground movement and vibration.

- Can be incorporated into the permanent structure.

Disadvantages:

- High cost and specialized equipment required.

- Relatively slow construction process.

- Requires careful control of bentonite slurry properties.

More Posts

Hardware and Software Requirements for ALLPLAN 2026

ALLPLAN System Requirements

Why Construction data should fit your project like a custom blueprint?

In an ideal world, ours would be an industry that ran on precision and fine margins but, as we all know, there is nothing precise

What is Design for Manufacturing and Assembly (DFMA)?

Source: Internet Design for Manufacturing and Assembly (DFMA) is a product design approach that focuses on simplifying the manufacturing and assembly processes to reduce production