What is Design for Manufacturing and Assembly (DFMA)?

Source: Internet

Design for Manufacturing and Assembly (DFMA) is a product design approach that focuses on simplifying the manufacturing and assembly processes to reduce production costs, improve quality, and shorten time to market.

Historical development

The origins of Design for Manufacturing and Assembly (DfMA) in construction date back to the 1940s, but it is only in recent years—thanks to advances in CAD software, robotics, and modular construction techniques—that these principles have become widely applicable to the construction industry.

Notable projects such as the rapid construction of modular hospitals during the COVID-19 pandemic, and Singapore’s Prefabricated Prefinished Volumetric Construction (PPVC) initiative, highlight how DfMA can significantly reduce both time and cost risks.

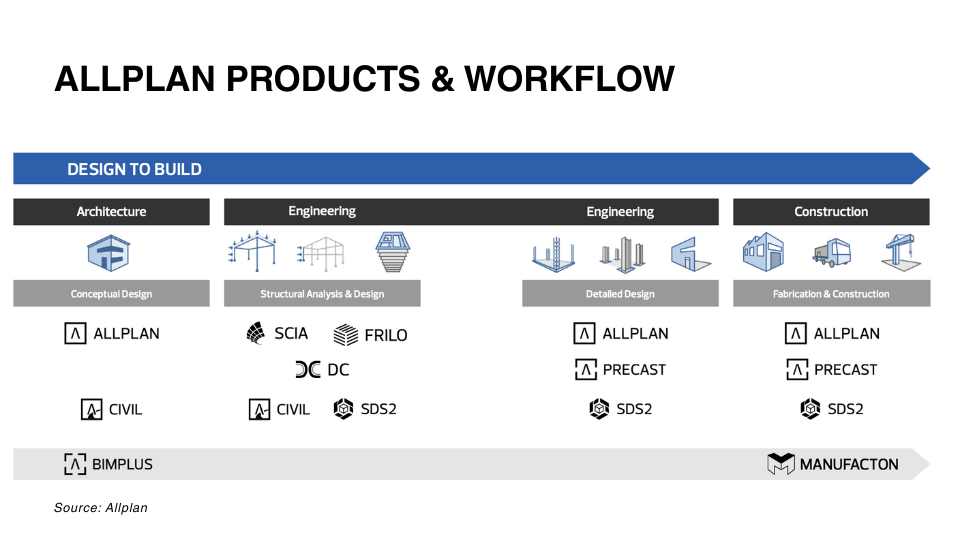

source: Allplan

Design for Manufacturing (DFM)

Focuses on designing products so they are easy and cost-effective to manufacture. This includes:

- Choosing materials that are readily available and easy to work with

- Designing parts that can be made with standard manufacturing processes (e.g., injection molding, CNC machining)

- Reducing the number of complex or tight-tolerance features

Goal: Minimize manufacturing complexity and cost without sacrificing product quality.

Design for Assembly (DFA)

Focuses on designing products so they are easy and quick to assemble. This includes:

- Reducing the number of parts

- Designing parts that are easy to align, orient, and secure

- Using standard fasteners or snap-fit features

Goal: Minimize the number of assembly steps, reduce human error, and shorten assembly time.

Benefits of DFMA:

- Lower manufacturing and assembly costs

- Faster product development cycles

- Improved product reliability and quality

- Easier automation or outsourcing of manufacturing

- Reduced material waste and better sustainability

- Lower error rate

- Higher product quality

- Streamlined manufacturing and assembly processes

- Resource efficient design and engineering

- Shorter construction time

- More accurate cost forecasts

Example: Let’s say you’re designing a coffee machine.

- Without DFMA: The design might use many custom screws, several small and delicate parts, and require complex steps to assemble.

- With DFMA: The design would aim to minimize part count (e.g., integrate multiple functions into one molded part), use snap-fits instead of screws, and ensure parts can only fit together in one correct way.

With DfMA, construction companies and general contractors gain planning security and reduce the risks in construction projects. DFMA is especially useful during the early design stages, where design decisions have the most significant impact on cost and manufacturability. Many companies use DFMA principles to create competitive, scalable, and high-quality products.

Barriers to implementing DfMA in construction

While Design for Manufacturing and Assembly offers clear advantages in terms of efficiency, quality, and sustainability, it is important to recognize that its implementation in construction is not without challenges.

Industry Fragmentation

- The construction industry involves many independent contractors, suppliers, and consultants.

- Lack of coordination makes it hard to implement integrated DfMA approaches across all parties.

Traditional Mindsets and Resistance to Change

- Many stakeholders are used to conventional construction methods.

- There’s often hesitation to adopt new workflows, tools, and technologies associated with DfMA.

Limited Digital and Technical Capabilities

- DfMA relies heavily on digital design tools (e.g., BIM, CAD) and advanced planning.

- Many firms, especially small to medium-sized ones, lack access to the necessary tools or skills.

Upfront Design Effort and Cost

- DfMA requires detailed planning and coordination early in the design phase.

- Clients and developers may resist the higher initial design cost, even though it results in long-term savings.

Supply Chain and Manufacturing Constraints

- Local supply chains may not support prefabrication or modular construction methods.

- Limited access to off-site manufacturing facilities or standardized components can hinder adoption.

Regulatory and Building Code Challenges

- Building codes and permitting processes may not be updated to accommodate modular or off-site construction methods.

- Approval timelines and inspections may not align with DfMA workflows.

Integration Challenges

- Ensuring that prefabricated elements integrate seamlessly with traditional site-built elements can be complex.

- Poor coordination can result in misfits, rework, or delays.

Skilled Labor Shortage for Off-Site Methods

- Prefabrication and modular construction require different skills compared to traditional trades.

- Workforce training programs may not yet support this shift.

Successfully implementing Design for Manufacturing and Assembly (DfMA) in construction requires seamless digital collaboration among a diverse group of stakeholders—including architects, engineers, manufacturers, contractors, and logistics providers. However, in practice, disparities in software platforms, data formats, and project objectives often result in communication breakdowns and data silos. Furthermore, traditional procurement models and fragmented responsibilities can hinder early manufacturer involvement, limiting the full potential of DfMA.

Successfully implementing Design for Manufacturing and Assembly (DfMA) in construction requires seamless digital collaboration among a diverse group of stakeholders—including architects, engineers, manufacturers, contractors, and logistics providers. However, in practice, disparities in software platforms, data formats, and project objectives often result in communication breakdowns and data silos. Furthermore, traditional procurement models and fragmented responsibilities can hinder early manufacturer involvement, limiting the full potential of DfMA.

How Allplan Supports DfMA in Construction

In short, DfMA is about making the right decisions in the design phase. This is exactly where ALLPLAN comes in with its “Design to build” philosophy: architects, engineers and construction professionals have all the tools and information they need to make the right decisions early on. From initial design concepts to detailed planning for production and assembly, every step can be managed within a unified software environment. This ensures seamless collaboration across disciplines and enables a smooth, efficient flow of information throughout the entire project lifecycle.

DOWNLOAD Unlocking the Secrets of DfMA: The Ultimate AEC-Guide e-book here >

More Posts

Hardware and Software Requirements for ALLPLAN 2026

ALLPLAN System Requirements

Why Construction data should fit your project like a custom blueprint?

In an ideal world, ours would be an industry that ran on precision and fine margins but, as we all know, there is nothing precise

EU Standards and Considerations for Retaining Walls

Source: Internet A retaining wall is a structure designed to hold back or retain soil, rock, or other materials behind it. It is commonly used